Automobile manufacturing is an integral part of the modern manufacturing ecological cluster, and is one of the major consumer goods in the "fast-paced" era. However, the traditional automobile manufacturing methods, processes complicated, expensive, more and more can not meet today's market demand. However, 3D printing technology is gradually changing the traditional industry is huge, and more and more enterprises begin to try to develop the use of 3D printing products, design and manufacturing, and create many amazing achievements!

Rolls-Royce's latest concept car will be heavily 3D printing technology

After Bentley, the famous luxury car brand Rolls-Royce also began to explore through 3D printing technology to develop cars. Recently, they have shown such a new Vision 100 concept car named "103EX". Some parts of the interior and it will be printed by 3D technology, which will be professional 3D printing service providers, by Rolls-Royce in its factory to complete the final treatment, so as to meet the personalized needs of buyers more and more high.

It is understood that this beautiful concept car is actually part of Rolls-Royce's owner BMW group Centennial celebrations, representing the company's next hundred years of Rolls-Royce's vision. In addition to 3D printing, it uses many other latest technologies. According to the design team headed by Giles Taylor, Vision 100 will rely on electric drive, so it will carry 2 250 kW motor before and after, and the chassis will be fully electronic design. Still, the car will retain Rolls-Royce's long engine hood and add two storage bins to the front wing panel. They are big enough to hold two suitcases, and they can reach out automatically.

Since the Vision 100 will also use automatic driving, it will only retain spacious back seats without front seat. Its virtual drivers are not only able to listen to the passengers' demands, deliver them safely to their destination, but also interact with the people inside the car through language activation.

Stratasys prints personalized parts for Japan's Daihatsu Copen sports car 3D

As a 3D printing giant, Stratasys has been working closely with well-known companies around the world. Recently, they have a famous Japanese car brand developed a cooperation agreement, will use the advanced 3D printing technology to create their own front and rear bumpers and fenders and other components, the "skin" is the lightweight sports car Copen, so as to meet the personalized needs of customers. Big hair is a well-known Japanese veteran car manufacturers, was founded in 1907 (shortly after will become a wholly owned subsidiary of TOYOTA), one hundred years has always been committed to the field of small cars, in the engine space, vehicle safety and environmental protection have advanced technology, is a leading global small car manufacturing enterprises, known as the "small car expert". Now aware of the importance of car personalization, they are also actively seeking progress, so they have found a powerful Stratasys.

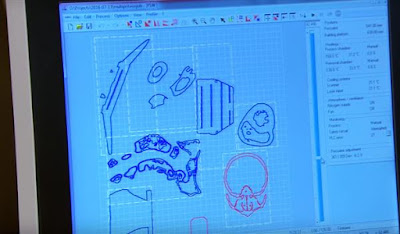

It is understood that, at present, Copen personalized "skin" has 15 models, a total of 10 colors, customers can choose. They are all commissioned by the 3D designer Sun Junjie design, and then through the flagship 3D printer Stratasys, Fortus made of ASA plastic, not only durable, but also very beautiful appearance. 3D printing brings us a lot of benefits, the most obvious of which is that the product development time has been greatly reduced from the previous few months to the present 2 weeks." "We will continue to work with Stratasys to expand the market with this kind of personalized plastic auto parts," said Osamu Fujishita, managing director of Daihatsu's corporate planning division."

Pure electric 3D print cars are about to start sale

The day before, according to foreign media reports, the United States Local company Motors LM3D Swim models is expected to become the first to enter the consumer market 3D printed car, the whole car 75% car components from the 3D print, using pure electric drive system, the pre-sale is expected to start in the second quarter of 2016, starting at $53 thousand (about RMB 336 thousand and 700 yuan).

According to foreign media reports, Local Motors company will strive to make this 3D print car completed, including crash testing and highway testing, including a series of certification. LM3D models will use the same chassis structure, and in appearance, will provide highly customized services.

Local Motors company revealed that, at present, LM3D series models 75% of body components from 3D printing, the materials used by 80% ABS plastic and 20% carbon fiber composition. In the future, 3D print car components account for the proportion of all components of the entire vehicle is expected to rise to 90%. The first production of LM3D Swim models will be launched in the second quarter of 2016 pre-sale, pre-sale price of 53 thousand U. S. dollars (about 336 thousand and 700 yuan) from, the first car is expected to be delivered to customers in early 2017.

Local Motors launches the world's first 3D printed electric bus

In June 16, 2016, 3D Motors, a print car company from Local, Arizona, launched a 3D printed automatic electric bus Olli, and part of the car was recyclable. Local Motors says this is a car that uses the IBM Watson's centralized cognitive learning platform for cars - Watson, Internet, of, Things (IoT), for, Automotive - the car. 3D print bus Olli square shape, very novel, there are 12 seats in the car. The unveiling of the car took place in the morning at a factory in National Motors in Local Harbor, about 10 miles from washington. It is understood that the same day, the car will be its designer Edgar Sarmiento, the company's CEO and co-founder John B. Rogers, from the Local Motors community to the new factory. From now on, this bus will be used in the km of Washington state and is expected to expand to Miami-Dade, County and Las Vegas by the end of 2016.

"Ollie provides intelligent, safe, sustainable transportation solutions that people have been looking forward to." "The Olli that installed the Watson will bring us into the world of self driving cars, and that's what our community has been quietly developing," Rogers said. We are now ready to speed up the promotion of this technology and will use it in almost every vehicle in the near future. I'm glad to see our open community with the most advanced automotive technology on top of it." It is worth mentioning that, Local Motors is in the form of crowdsourcing, open its car in its open community. It is reported that installed in the car shell below Olli 3D printing is the world's most advanced automotive technology, including IBM Watson Internet of Things for Automotive, which is a computing system based on cloud computing, a large number of traffic data can be placed inside the car through more than 30 sensors in the analysis and study to collect. Thanks to the Local Motors's open vehicle development process, these sensors can be adjusted according to the needs of passengers and local characteristics. In addition, the system provides specialized API (voice to text, natural language classifiers, entity extraction, and text to speech) to create a number of useful features for the bus.

Automatic driving technology provides all the ability to navigate a bus driver with the use of Phoenix in Wings, Olli also reproduced the driver should have social function: this car 3D bus passengers can print to the car to ask questions, and to discuss issues such as the car is how the development, where they were going, in some under the condition of the car is how to make a decision on such issues driving. IBM Watson makes Olli able to answer such questions naturally, and offers popular restaurants, tourist attractions and other suggestions. Developers hope to help passengers relax during this journey.

"Cognitive provides an incredible opportunity to use all computing, networking equipment from connection to objects, including all sensors and systems on the vehicle, the data flow for customers to create a unique customized experience." IBM Watson company business and education general manager Harriet Green said: "IBM is very excited to work with Local Motors, IBM Watson's cognitive computing capabilities into the Olli, provide a unique personalized experience for every passenger, while helping to change human traffic patterns." The automatic driving of the 3D print bus Ollie has attracted a lot of interest, for example, Miami-Dade county is already preparing a pilot project for such a self driving automobile.

It is reported that Local Motors National Harbor company located in the plant will serve as the co creation concept car a public space -- to know Crowdsourcing development mode is the building blocks of the local car company's new national port facilities. The first iteration of the Olli will remain in the National Habor throughout the summer, when visitors will interact with it at the stated time.