3D printing out of Filament silk? These steps teach you to solve quickly!

The Filament of the disc is jammed, which can cause the silk to be impeded?

3D printing out of Filament, why?

No Filament when printing;

Insufficient amount of Filament;

Fault generating;

Once the Filament is not smooth, you need specific analysis of the specific problems, one by one to investigate the reasons:

Is the disc sticking?

Is the print nozzle plugged?

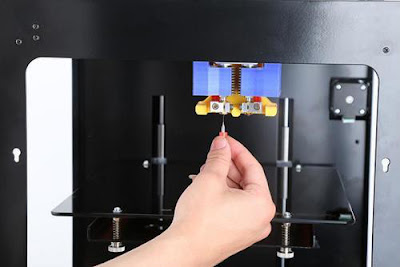

If the print nozzle is blocked, follow these steps:

1. heating print head, from the print head to take out the material (Note: be sure to print the head in the case of heating out of the material, under the cooling state forcibly pull out will lead to more serious congestion);

2. Use a steel wire with a diameter smaller than the nozzle or a minimum six inner angle wrench to clear the nozzle;

3. the nozzle temperature manually raised, manually to the throat extrusion Filament, so that nozzle normal spinning;

4. pull out the Filament, the Filament is inserted into the pipes again, such as Filament melting out, repeated several times until the final Filament smooth (the purpose is to make the semi molten wire residue in nozzle blockage or adhesion out);

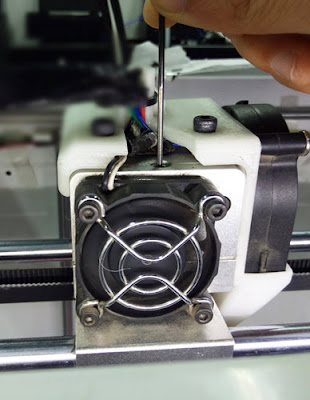

If the above method can not be solved, you need to remove the print nozzle:

1. Remove the nozzle and heat the part of the adhesive material in the nozzle with the spray gun. Clean the materials and impurities sticking to the nozzle;

2. after cleaning or replacement nozzle re installed, and if the yarn is not smooth, we should consider whether the need to replace the pipe inside the PTFE tube, if the PTFE tube deformation, it will cause serious plug;

3. reinstall the print nozzle, you can smooth out the Filament;

Alunar 3D Printer Extruder adopts new structure, nozzle is easier to assemble and disassemble, avoid plug problem from the source. In addition to the filament is also very important, good quality filament to a great extent, can avoid this problem.

Thursday, June 29, 2017

Tuesday, June 27, 2017

Top 5 Tips You Have to Recognize the 3D Print Follow-up Processing Problem

The advantages of 3D printing are undeniable, but when it comes to the cost of post-processing, it often becomes a big headache".

Not long ago, Rize, a start-up in Boston, USA, has just launched an industrial class desktop 3D printer called Rize One, which is known as a print product that can be used directly without the need for post-processing. It is by virtue of this big bright spot, Rize One quickly caught a lot of 3D printing enterprise appetite. Before launching the research, Frank Marangell, chief executive of Rize, said that the innovation degree of rapid prototyping technology and materials was reflected in strength, surface accuracy, color, zero post-processing and environmental protection.

But the real research, senior practitioners the former vice president, chief executive of Rize, the Stratasys operation, suddenly feel that the real key should be postprocessing this link with rapid prototyping the most in the crowd is used in the fixture and mould manufacturing, and these people are longing for a can help them quickly complete the postprocessing plan. The post-processing of the FDM process requirements is relatively simple, but the supporting structures must also be removed and then polished, polished or sprayed:

A 3D printing model may take half a day to soak in a sodium hydroxide solution to remove the support material.

FDM post-processing is not only harmful to the environment, but also difficult for operators. You have to wear gloves and pliers. But after doing this post-processing, the parts that come out can easily let you PK other programs:

Such as light cured (SLA), after printing, need to soak in alcohol, and then use UV light curing, and then to support, grinding. Selective laser sintering (SLS) is compared to Frank Marangell for "archaeological excavation". You have to slowly remove most of the powder in a sealed chamber and rinse it with water.

In addition to making the components more robust, Rize One will be in print in the supporting structure between it and print a rejection of the ink jet itself is called Release One, which can support the removal of ink made easier (only 30 to 45 seconds), but will not affect the print quality. In addition, it uses a unique enhanced polymer deposition (APD) technology that can change the nature of each print element, producing a uniform object that is 2 times the strength of the FDM print.

The Rize One desktop 3D printer in the Beta test phase shortens the post processing time from a few hours to less than a minute.

Some post-processing even takes several days. Such a time-consuming cost is enormous, so Rize One commissioned a manufacturing consultant Todd Grimm to do a special report on the impact of postprocessing on 3D printing. Here are 5 main aspects of this report that show the cost of 3D post processing:

1. Waste of Production Time

The report showed that the 3D print time increased by 6 hours each, and the post processing time increased by 1 hours.

If your company also needs to do post-processing, 3D printing can not break the bottleneck of time, but may extend the product listing time.

"Because the postprocessing block, Newell Rubbermaid efficiency 3D print reached only 60%," Frank said, "imagine if your weekly factory production operation only 3 days, also a lot of time to do the postprocessing would be very inefficient."

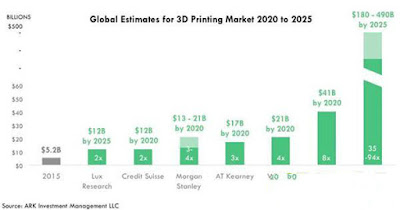

It is predicted that the global 3D printing market will reach $490 billion in 2025. However, if the threshold for post processing does not cross, this prediction is likely to face the risk of premature death.

2. Increase Labor Costs

Grinding and finishing will also consume a lot of manpower, and some jobs still require highly skilled personnel. In the above report, the total wage of 4-10 printers running is about 100 thousand -50 $/ year, and the manpower cost directly after print processing is about $50 thousand / year for each printer.

3. Reduce Employee Productivity Creativity

If employees spend too much time on finishing and polishing these processes, they will reduce the time for innovation. Originally, these hours could be used to develop and speed up production. Recruitment of professional post - processing technicians is also not easy.

4. Quality Is Not Reliable

The advanced approach to 3D printing to make models would have been a horrible sight if you had to use the tools such as art knives, sandpaper and nozzles to do model post-processing.

"The fact is, whatever you put those who support the cutting much good, so will always leave some corner scrap," Marangell said, "this will give parts of accurate geometry original clogging, it is a process of hate."

If the parts are damaged, you have to start all over again and even repeat the process, which wastes more manpower, printing time and materials.

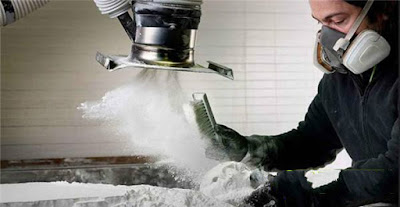

5. Is Harmful to The Environment

In the Grimm survey, a medical device company, Chen Dao, said: "3D print operation is the largest source of hazardous waste in the entire research and development plant".

The SLA model may be immersed in a caustic liquid such as sodium hydroxide. The high risk factor is clearly visible, and inhalation of ABS and PLA material has proved to be very dangerous.

"All of these things, without a single room, dust would be everywhere," Marangell said, pointing to a SLS device.

These costs add up is not a small expenditure, you need to properly dispose of these materials, but also good workers with gloves, clothes and dust respirator, you also need a space to ensure the safe operation of ventilation.

So, after treatment costs are high, time-consuming and harmful to the environment, what should we do?

"Because all 3D printing technologies require post-processing, experienced users will find this very annoying. But it's unwise to give up 3D printing.

"FDM is your easiest 3D print," Frank says. "It's polluting the environment and annoying. You also need gloves and pliers, but eventually you'll find it's the best choice.". If you want a trustworthy FDM 3D Printer can go Alunar 3D Printer Store.

Officially launched next year, Rize One is expected to change this situation, Reebok has indicated that using it can reduce the operation time of 50%.

Rize said that the new technology and the secret formula will help 3D printing technology out of the laboratory and in the office and factory air plant, it is the beginning of this century 2D laser printer commercialized as. Revolutionary.

"You still need a space laboratory, to complete complex postprocessing," Frank said, "but when the design engineer, want to want to make a prototype tool production engineer or doctor to make dental dental cast to have finished. They just buy an 3D printer instead of using a particular lab to print it."

Not long ago, Rize, a start-up in Boston, USA, has just launched an industrial class desktop 3D printer called Rize One, which is known as a print product that can be used directly without the need for post-processing. It is by virtue of this big bright spot, Rize One quickly caught a lot of 3D printing enterprise appetite. Before launching the research, Frank Marangell, chief executive of Rize, said that the innovation degree of rapid prototyping technology and materials was reflected in strength, surface accuracy, color, zero post-processing and environmental protection.

But the real research, senior practitioners the former vice president, chief executive of Rize, the Stratasys operation, suddenly feel that the real key should be postprocessing this link with rapid prototyping the most in the crowd is used in the fixture and mould manufacturing, and these people are longing for a can help them quickly complete the postprocessing plan. The post-processing of the FDM process requirements is relatively simple, but the supporting structures must also be removed and then polished, polished or sprayed:

A 3D printing model may take half a day to soak in a sodium hydroxide solution to remove the support material.

FDM post-processing is not only harmful to the environment, but also difficult for operators. You have to wear gloves and pliers. But after doing this post-processing, the parts that come out can easily let you PK other programs:

Such as light cured (SLA), after printing, need to soak in alcohol, and then use UV light curing, and then to support, grinding. Selective laser sintering (SLS) is compared to Frank Marangell for "archaeological excavation". You have to slowly remove most of the powder in a sealed chamber and rinse it with water.

In addition to making the components more robust, Rize One will be in print in the supporting structure between it and print a rejection of the ink jet itself is called Release One, which can support the removal of ink made easier (only 30 to 45 seconds), but will not affect the print quality. In addition, it uses a unique enhanced polymer deposition (APD) technology that can change the nature of each print element, producing a uniform object that is 2 times the strength of the FDM print.

The Rize One desktop 3D printer in the Beta test phase shortens the post processing time from a few hours to less than a minute.

Some post-processing even takes several days. Such a time-consuming cost is enormous, so Rize One commissioned a manufacturing consultant Todd Grimm to do a special report on the impact of postprocessing on 3D printing. Here are 5 main aspects of this report that show the cost of 3D post processing:

1. Waste of Production Time

The report showed that the 3D print time increased by 6 hours each, and the post processing time increased by 1 hours.

If your company also needs to do post-processing, 3D printing can not break the bottleneck of time, but may extend the product listing time.

"Because the postprocessing block, Newell Rubbermaid efficiency 3D print reached only 60%," Frank said, "imagine if your weekly factory production operation only 3 days, also a lot of time to do the postprocessing would be very inefficient."

It is predicted that the global 3D printing market will reach $490 billion in 2025. However, if the threshold for post processing does not cross, this prediction is likely to face the risk of premature death.

2. Increase Labor Costs

Grinding and finishing will also consume a lot of manpower, and some jobs still require highly skilled personnel. In the above report, the total wage of 4-10 printers running is about 100 thousand -50 $/ year, and the manpower cost directly after print processing is about $50 thousand / year for each printer.

If employees spend too much time on finishing and polishing these processes, they will reduce the time for innovation. Originally, these hours could be used to develop and speed up production. Recruitment of professional post - processing technicians is also not easy.

4. Quality Is Not Reliable

The advanced approach to 3D printing to make models would have been a horrible sight if you had to use the tools such as art knives, sandpaper and nozzles to do model post-processing.

"The fact is, whatever you put those who support the cutting much good, so will always leave some corner scrap," Marangell said, "this will give parts of accurate geometry original clogging, it is a process of hate."

If the parts are damaged, you have to start all over again and even repeat the process, which wastes more manpower, printing time and materials.

5. Is Harmful to The Environment

In the Grimm survey, a medical device company, Chen Dao, said: "3D print operation is the largest source of hazardous waste in the entire research and development plant".

The SLA model may be immersed in a caustic liquid such as sodium hydroxide. The high risk factor is clearly visible, and inhalation of ABS and PLA material has proved to be very dangerous.

"All of these things, without a single room, dust would be everywhere," Marangell said, pointing to a SLS device.

These costs add up is not a small expenditure, you need to properly dispose of these materials, but also good workers with gloves, clothes and dust respirator, you also need a space to ensure the safe operation of ventilation.

So, after treatment costs are high, time-consuming and harmful to the environment, what should we do?

"Because all 3D printing technologies require post-processing, experienced users will find this very annoying. But it's unwise to give up 3D printing.

"FDM is your easiest 3D print," Frank says. "It's polluting the environment and annoying. You also need gloves and pliers, but eventually you'll find it's the best choice.". If you want a trustworthy FDM 3D Printer can go Alunar 3D Printer Store.

Officially launched next year, Rize One is expected to change this situation, Reebok has indicated that using it can reduce the operation time of 50%.

Rize said that the new technology and the secret formula will help 3D printing technology out of the laboratory and in the office and factory air plant, it is the beginning of this century 2D laser printer commercialized as. Revolutionary.

|

| Not to support the transparent |

"You still need a space laboratory, to complete complex postprocessing," Frank said, "but when the design engineer, want to want to make a prototype tool production engineer or doctor to make dental dental cast to have finished. They just buy an 3D printer instead of using a particular lab to print it."

Sunday, June 25, 2017

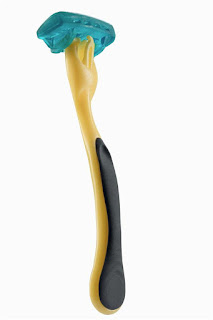

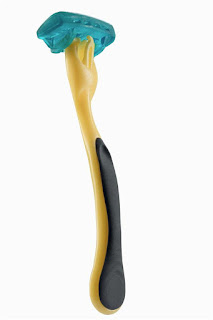

Creative 3D Print Cleaner, Using 3D Printing Technology to Change Life

In the congregation to raise the site Kickstarter, often there will be some very strange gadgets. Although some things are really simple things, they can change our lives. One interesting thing about Kickstarter recently is that it's an innovative 3D print gadget, especially for handheld mixers that allow users to clean things more easily.

Cleaning an egg whisk is not an interesting job. There are always some blind corners that can not be cleaned properly. But this 3D print cleaning brush can change the status quo, easy to remove every corner of the food residue. It is not cleaned or rinsed with water, but is completely cleaned by squeezing it out. Have to say, this must be a kitchen artifact.

According to Zhi Ke 3D understand, this 3D print cleaning brush was invented by Matthew Michel. In fact, this is a very simple concept, but when he realized it with 3D printing, it turned into a creative design. The method is simple. You just need to put the 3D print brush out of the back, start with the holding mixer, and then push out slowly, and the extra food will be completely removed. Not only can the blender be easily cleaned, but it can also be used to the full extent of all the food.

But in fact, this is not a Matthew Michel a person's credit. He also worked with 3D designer Robert Apodaca and engineer Arpita Soni to slowly implement the idea from a small concept into today's creative object. According to them, now 3D printing cleaning brush landing Kickstarter, there is an important gimmick is 3D printing this technology. They have worked with a local 3D printing company to complete print production.

At present, this 3D print cleaning brush has far exceeded the beginning of their congregation raised target $10 thousand, now has reached $50 thousand. The earliest deals are over, but now users can still get a $23 Stainless Steel Blender, and move on!

Cleaning an egg whisk is not an interesting job. There are always some blind corners that can not be cleaned properly. But this 3D print cleaning brush can change the status quo, easy to remove every corner of the food residue. It is not cleaned or rinsed with water, but is completely cleaned by squeezing it out. Have to say, this must be a kitchen artifact.

According to Zhi Ke 3D understand, this 3D print cleaning brush was invented by Matthew Michel. In fact, this is a very simple concept, but when he realized it with 3D printing, it turned into a creative design. The method is simple. You just need to put the 3D print brush out of the back, start with the holding mixer, and then push out slowly, and the extra food will be completely removed. Not only can the blender be easily cleaned, but it can also be used to the full extent of all the food.

But in fact, this is not a Matthew Michel a person's credit. He also worked with 3D designer Robert Apodaca and engineer Arpita Soni to slowly implement the idea from a small concept into today's creative object. According to them, now 3D printing cleaning brush landing Kickstarter, there is an important gimmick is 3D printing this technology. They have worked with a local 3D printing company to complete print production.

At present, this 3D print cleaning brush has far exceeded the beginning of their congregation raised target $10 thousand, now has reached $50 thousand. The earliest deals are over, but now users can still get a $23 Stainless Steel Blender, and move on!

Friday, June 23, 2017

The Hospital Uses 3D Printing Technology to Assist in The Treatment of Fractures

With the development of 3D printing technology, 3D printed anatomical models are gradually appearing in hospitals around the world, and more and more surgeons are using it to prepare very unusual and highly complex operations. So far, we have seen the 3D print heart model that saved the life of a Russian baby born 5 days old with congenital heart defects. Although these types of projects are usually one-off and rare, many hospitals also make medical models systematically using 3D printing technology. It is located in Holland, Tilburg Elisabeth-TweeSteden hospital is also in the use of 3D printer to print the medical model.

Specifically, the focus of this new 3D printing system will be placed in the fracture, which aims to help the Tilburg trauma surgeons prepare special complex fractures. The initiative was proposed by surgeon Mike Bemelman, which has been tested on many body parts including the pelvis, hips, knees, and even a life size rib. All models are based on patient CT scans. Now, according to doctors, the 3D printer will remain open for 24 hours. It takes 16 hours to complete the pelvic model.

But Bemelman explains that its added value is unlimited. "For a surgeon, these 3D models are very helpful to me because I can see the exact fracture site and make a quick surgical procedure. Even very small fractures that are often overlooked on the screen can become very obvious, "he said. But before that, the digital program required surgeons to take a shot through the CT scan to obtain a complete image of the fracture.

All collected data were then used to establish a very accurate and rapid surgical plan. "I can be in the 3D printing model marked figures clearly show the need to take steps in the process of the operation sequence," he said. What's more, using the model, we can cut the size and position of the screws on the curved metal plate before surgery, which reduces the operation time."

While the patients from this new technology to get the benefit, but the surgeon is still being tested, trying to uncover the full potential of medical 3D printing technology, researcher Dr. Lars Brouwers will conduct a new study of NAZB using 3D printing technology. He will submit a variety of cases to trauma surgeons, including 3D print models that use CT scan data to print diseased parts of patients.

According to Brouwers, they expect the 3D print model to bring a faster and more effective way for fracture classification and treatment. "We also believe that these 3D print models can help young inexperienced surgeons adapt to particularly complex procedures. "The researchers added.

Specifically, the focus of this new 3D printing system will be placed in the fracture, which aims to help the Tilburg trauma surgeons prepare special complex fractures. The initiative was proposed by surgeon Mike Bemelman, which has been tested on many body parts including the pelvis, hips, knees, and even a life size rib. All models are based on patient CT scans. Now, according to doctors, the 3D printer will remain open for 24 hours. It takes 16 hours to complete the pelvic model.

But Bemelman explains that its added value is unlimited. "For a surgeon, these 3D models are very helpful to me because I can see the exact fracture site and make a quick surgical procedure. Even very small fractures that are often overlooked on the screen can become very obvious, "he said. But before that, the digital program required surgeons to take a shot through the CT scan to obtain a complete image of the fracture.

All collected data were then used to establish a very accurate and rapid surgical plan. "I can be in the 3D printing model marked figures clearly show the need to take steps in the process of the operation sequence," he said. What's more, using the model, we can cut the size and position of the screws on the curved metal plate before surgery, which reduces the operation time."

While the patients from this new technology to get the benefit, but the surgeon is still being tested, trying to uncover the full potential of medical 3D printing technology, researcher Dr. Lars Brouwers will conduct a new study of NAZB using 3D printing technology. He will submit a variety of cases to trauma surgeons, including 3D print models that use CT scan data to print diseased parts of patients.

According to Brouwers, they expect the 3D print model to bring a faster and more effective way for fracture classification and treatment. "We also believe that these 3D print models can help young inexperienced surgeons adapt to particularly complex procedures. "The researchers added.

Wednesday, June 21, 2017

Does Adidas Want to Make Shoes with 3D Printing?

Popular shoe manufacturer 3D printing technology really is not blowing out, after yesterday released the new 100-lun brand sports shoes sports shoes ms066 3D printing, the well-known sports brand Adidas also today released their new research and development of 3D printing UltraBoost Uncaged Parley sports shoes. It is reported that the shoes used almost all of the materials from the ocean recycled plastic, and then produced using 3D printing technology.

A year ago, Adidas worked with Parley (Parley, an organization that aims to increase awareness of marine pollution and plastic waste), using plastic recycled from the ocean and making 3D sneakers. Obviously, the structure of the experiment is impressive because the shoes combine the ocean recycled plastic and Adidas's 3D print futurecraft bottom. Although the experiment shows that the footwear industry has taken an important step towards sustainability, they are not quite ready to retail it. It is still a concept shoe. But now, Adidas and Parley have decided to release their UltraBoost Uncaged Parley sneakers next month at a retail price of $200. Initially, Adidas will introduce 7000 pairs of sports shoes, but according to the company revealed that the next year, they will launch more than 1 million pairs.

And the new UltraBoost Uncaged Parley sneakers don't seem to add 3D printing components, because 3D printing isn't the ideal method of manufacturing for one million pairs of sneakers. But the sports shoes they make will still be recycled from the ocean, including shoelaces, heels, straps, and laces, all of which are renewable materials. In fact, each pair of shoes contains as many as 11 plastic bottles. According to Adidas officials, most of the UltraBoost Uncaged Parley sneakers are made from coastal areas of Maldives. With the integration of renewable materials Adidas continues to expand, the company even said it hopes to eventually eliminate it from the entire supply chain of plastic, which is a great progress for the company, but also worth mentioning the concept of environmental protection and fashion manufacturing linked as a whole.

A year ago, Adidas worked with Parley (Parley, an organization that aims to increase awareness of marine pollution and plastic waste), using plastic recycled from the ocean and making 3D sneakers. Obviously, the structure of the experiment is impressive because the shoes combine the ocean recycled plastic and Adidas's 3D print futurecraft bottom. Although the experiment shows that the footwear industry has taken an important step towards sustainability, they are not quite ready to retail it. It is still a concept shoe. But now, Adidas and Parley have decided to release their UltraBoost Uncaged Parley sneakers next month at a retail price of $200. Initially, Adidas will introduce 7000 pairs of sports shoes, but according to the company revealed that the next year, they will launch more than 1 million pairs.

And the new UltraBoost Uncaged Parley sneakers don't seem to add 3D printing components, because 3D printing isn't the ideal method of manufacturing for one million pairs of sneakers. But the sports shoes they make will still be recycled from the ocean, including shoelaces, heels, straps, and laces, all of which are renewable materials. In fact, each pair of shoes contains as many as 11 plastic bottles. According to Adidas officials, most of the UltraBoost Uncaged Parley sneakers are made from coastal areas of Maldives. With the integration of renewable materials Adidas continues to expand, the company even said it hopes to eventually eliminate it from the entire supply chain of plastic, which is a great progress for the company, but also worth mentioning the concept of environmental protection and fashion manufacturing linked as a whole.

Monday, June 19, 2017

The United States Hospital by 3D Printing Technology Development Liposuction Medical Equipment

BioSculpture Technology is working in the Central Hospital of New York and New York Presbyterian affiliated orthopaedic surgeon Robert Cucin company, it is reported that the company recently used 3D printing technology developed a new type of surgical instruments, can be used for the treatment of obesity.

Liposuction, a surgical procedure that removes excess fat from the body's parts, is now used mainly in obese people. According to the American Society for cosmetic and plastic surgery (ASAPS), the number of liposuction operations increased by more than 16% in 2016 compared with 2015.

Dr. ASAPS, President of Jack Fisher, said the increase in liposuction surgery could be attributed to the emergence of innovative technologies such as 3D printing, which have been successful in reducing the risk of liposuction. "Technological advances, smaller surgeries are making these new looking" surgeries "more attractive.". More and more people are starting to invest themselves again. "Dr. Fisher says.

BioSculpture Technology is one of several companies that are currently trying to use 3D printing technology, and the company uses the new technology in order to make patients safer and more effective bariatric surgery. For most surgery, liposuction surgery time, the process and the overall efficiency depends heavily on the quality and ability of surgical instruments. If the surgeon provides specially customized and designed medical equipment, the operation time will be reduced and the risk of operation will be greatly reduced.

The use of 3D printing technology and 3D imaging technology, BioSculpture Technology CEO Robert Cucin, is trying to liposuction physicians make appropriate medical equipment.

Dr. Cucin said, most manufacturers and surgical equipment developers in the development of medical instruments, and did not notice how important human organs precision, because of the internal and external human body organs are quite fine, if the operation of medical equipment can be the perfect adaptation of human body organs, so can to some extent reduce the risk of liposuction surgery.

Though many attempts, also experienced numerous mistakes, Dr. Cucin's team still unremittingly, still trying to optimize the development process and the operation of liposuction medical equipment. Dr. Cucin's goal is to provide customized surgical instruments for each operation phase.

Dr Cucin explained: "many doctors have worked hard to safely extract fat, but over the years they have had little success.". Our goal is to enable 3D printing to improve the safety of surgery." "This particular 3D print device allows us to place it in an extremely small incision that removes fat from the stomach and removes fat hidden under the muscles," he says. You know, in the past, if you want to remove these parts of fat, you can only cut off. So, in general, we're taking fat out safely in an unprecedented way of innovation, bringing people closer to what they want to be."

The ultimate goal of all liposuction operations is to minimize injury to the patient's body and internal structure and safely extract excessive amounts of fat deposits. Therefore, after careful analysis of liposuction, as a target for each muscle, tissue, and body part of the structure, the company is fully guaranteed to extract fat without cutting. Dr Cucin points out that the combination of 3D printing, 3D imaging, and other revolutionary technologies will enable BioSculpture technology and other companies to develop safer devices for patients.

Bariatric surgery, however, has an incredible risk, and the patient will probably have many unexpected complications after the recovery process. NHS is a publicly funded national health care system in the United Kingdom. It points to some common complications of infection, thrombosis, internal bleeding, gastric banding, food intolerance, gallstones, and so on.

Complications such as food intolerance are more psychological than physical. But, BioSculpture says, 3D imaging aids can prevent internal bleeding, infection, and gallstones (in about 20% of people).

Almost every patient had symptoms such as loose skin and gallstones. Skin diseases are usually not easy to treat. Once the disease develops, it is usually a permanent disease, because the space previously filled with excess fat can not be recombined. In most cases, skin complications are mostly caused by an imbalance of fat aspiration.

However, through the 3D printing structure, researchers can predict by mathematical calculation how much excess skin will be produced after extracting a certain amount of fat deposits.

Using 3D printing technology related medical equipment, so that surgeons will be able to patients for safer, more effective liposuction surgery, so beautiful "zero" risk.

Liposuction, a surgical procedure that removes excess fat from the body's parts, is now used mainly in obese people. According to the American Society for cosmetic and plastic surgery (ASAPS), the number of liposuction operations increased by more than 16% in 2016 compared with 2015.

Dr. ASAPS, President of Jack Fisher, said the increase in liposuction surgery could be attributed to the emergence of innovative technologies such as 3D printing, which have been successful in reducing the risk of liposuction. "Technological advances, smaller surgeries are making these new looking" surgeries "more attractive.". More and more people are starting to invest themselves again. "Dr. Fisher says.

BioSculpture Technology is one of several companies that are currently trying to use 3D printing technology, and the company uses the new technology in order to make patients safer and more effective bariatric surgery. For most surgery, liposuction surgery time, the process and the overall efficiency depends heavily on the quality and ability of surgical instruments. If the surgeon provides specially customized and designed medical equipment, the operation time will be reduced and the risk of operation will be greatly reduced.

The use of 3D printing technology and 3D imaging technology, BioSculpture Technology CEO Robert Cucin, is trying to liposuction physicians make appropriate medical equipment.

Dr. Cucin said, most manufacturers and surgical equipment developers in the development of medical instruments, and did not notice how important human organs precision, because of the internal and external human body organs are quite fine, if the operation of medical equipment can be the perfect adaptation of human body organs, so can to some extent reduce the risk of liposuction surgery.

Though many attempts, also experienced numerous mistakes, Dr. Cucin's team still unremittingly, still trying to optimize the development process and the operation of liposuction medical equipment. Dr. Cucin's goal is to provide customized surgical instruments for each operation phase.

Dr Cucin explained: "many doctors have worked hard to safely extract fat, but over the years they have had little success.". Our goal is to enable 3D printing to improve the safety of surgery." "This particular 3D print device allows us to place it in an extremely small incision that removes fat from the stomach and removes fat hidden under the muscles," he says. You know, in the past, if you want to remove these parts of fat, you can only cut off. So, in general, we're taking fat out safely in an unprecedented way of innovation, bringing people closer to what they want to be."

The ultimate goal of all liposuction operations is to minimize injury to the patient's body and internal structure and safely extract excessive amounts of fat deposits. Therefore, after careful analysis of liposuction, as a target for each muscle, tissue, and body part of the structure, the company is fully guaranteed to extract fat without cutting. Dr Cucin points out that the combination of 3D printing, 3D imaging, and other revolutionary technologies will enable BioSculpture technology and other companies to develop safer devices for patients.

Bariatric surgery, however, has an incredible risk, and the patient will probably have many unexpected complications after the recovery process. NHS is a publicly funded national health care system in the United Kingdom. It points to some common complications of infection, thrombosis, internal bleeding, gastric banding, food intolerance, gallstones, and so on.

Complications such as food intolerance are more psychological than physical. But, BioSculpture says, 3D imaging aids can prevent internal bleeding, infection, and gallstones (in about 20% of people).

Almost every patient had symptoms such as loose skin and gallstones. Skin diseases are usually not easy to treat. Once the disease develops, it is usually a permanent disease, because the space previously filled with excess fat can not be recombined. In most cases, skin complications are mostly caused by an imbalance of fat aspiration.

However, through the 3D printing structure, researchers can predict by mathematical calculation how much excess skin will be produced after extracting a certain amount of fat deposits.

Using 3D printing technology related medical equipment, so that surgeons will be able to patients for safer, more effective liposuction surgery, so beautiful "zero" risk.

Saturday, June 17, 2017

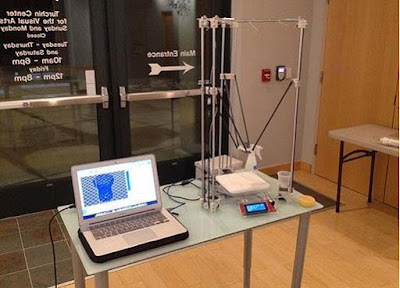

How did the American Professor Make Homemade Ceramic 3D Printers at Home?

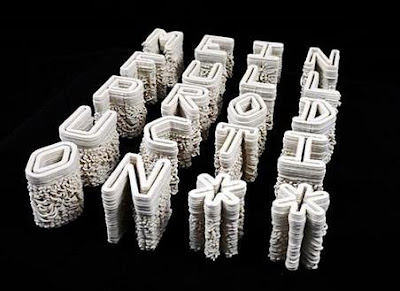

Ceramic printing has been a hot topic in the 3D printing world, but only a handful of 3D printers can print it. However, the Appalachian State University professor of graphic design TaekyeomLee is to prove to people, you can print DIY ceramics at home. He made a ceramic 3D printer and used it to print exquisite artwork.

As Lee revealed, the project is beyond the scope of academic research, and he wants to explore data modeling and graphic design through 3D printing technology. He hopes to combine print, artwork, ceramics, and 3D printing. He said: "desktop machines have interested me because they don't take up too much space. With this new tool, I can make more complex shapes."

But making a 3D printer isn't easy. About a year ago, Lee purchased accessories for 3D printers and started assembling on an open source file on the internet. Although many difficulties encountered in the air sealing problem, but with a long time of hard work and great patience, he finally developed a set of extrusion system, to be able to 80psi the pressure extrusion clay materials for printing.

After the printer is finished, the treatment of clay material is also a difficult problem. Especially for the grasp of viscosity is very difficult, too dry can not be squeezed out; too soft, printed matter easily collapse. Eventually, he installed 3 small 120mm fans on the print platform, which quickly dried up the prints and prevented them from collapsing. Although not the best method, he is still improving.

According to Suzhou Ke 3D printing understand, Lee is still improving the printer, so that it can print out more complex shapes of objects. With this printer, Lee prints a lot of 3D print, artwork, and fine sculptures. At present, this printer can print clay, clay, ceramics, and even copper, clay and other materials. Of course, the clay material must be sintered to complete the final print after printing.

As Lee revealed, the project is beyond the scope of academic research, and he wants to explore data modeling and graphic design through 3D printing technology. He hopes to combine print, artwork, ceramics, and 3D printing. He said: "desktop machines have interested me because they don't take up too much space. With this new tool, I can make more complex shapes."

But making a 3D printer isn't easy. About a year ago, Lee purchased accessories for 3D printers and started assembling on an open source file on the internet. Although many difficulties encountered in the air sealing problem, but with a long time of hard work and great patience, he finally developed a set of extrusion system, to be able to 80psi the pressure extrusion clay materials for printing.

After the printer is finished, the treatment of clay material is also a difficult problem. Especially for the grasp of viscosity is very difficult, too dry can not be squeezed out; too soft, printed matter easily collapse. Eventually, he installed 3 small 120mm fans on the print platform, which quickly dried up the prints and prevented them from collapsing. Although not the best method, he is still improving.

According to Suzhou Ke 3D printing understand, Lee is still improving the printer, so that it can print out more complex shapes of objects. With this printer, Lee prints a lot of 3D print, artwork, and fine sculptures. At present, this printer can print clay, clay, ceramics, and even copper, clay and other materials. Of course, the clay material must be sintered to complete the final print after printing.

Thursday, June 15, 2017

3D printing technology uses printing personalized tableware

Personalized tableware is now available everywhere, but have you ever used 3D print tableware and personalized tableware?

A study from the Columbia University in the United States said that 3D printing can produce food safety tableware, and enough to change the hotel's service ecology. In their study, all the dishes used in the 3D print dinner were made using 3D printing technology. Making mat with Objet company Connex 500 PolyJet 3D printer, tableware made of stainless steel material 3D printing to meet food safety production; for the first time using 3D printing ceramic tableware, the theme of the feast is Italian dinner, the Venice mask design elements design.

Alunar recommends several versions of the same 3D prints for you.

Although 3D printing is a very advanced technology, there are some designers who somehow connect it with the art of the past. Recently, Czech furniture Lauriger has introduced a new set of tableware series, trying to use 3D printing to recreate the country once glorious cubism.

The concept of customization has become popular, and the advantages of 3D printing technology allow customized concepts to penetrate more into the field of personalized demand. In the past, consumers bought things that were mass-produced, and if they needed personalized things, they would have to find designers to make them. And now, 3D print customization can be used to make ergonomic dishes, and even help people with disabilities.

A study from the Columbia University in the United States said that 3D printing can produce food safety tableware, and enough to change the hotel's service ecology. In their study, all the dishes used in the 3D print dinner were made using 3D printing technology. Making mat with Objet company Connex 500 PolyJet 3D printer, tableware made of stainless steel material 3D printing to meet food safety production; for the first time using 3D printing ceramic tableware, the theme of the feast is Italian dinner, the Venice mask design elements design.

Alunar recommends several versions of the same 3D prints for you.

Although 3D printing is a very advanced technology, there are some designers who somehow connect it with the art of the past. Recently, Czech furniture Lauriger has introduced a new set of tableware series, trying to use 3D printing to recreate the country once glorious cubism.

The concept of customization has become popular, and the advantages of 3D printing technology allow customized concepts to penetrate more into the field of personalized demand. In the past, consumers bought things that were mass-produced, and if they needed personalized things, they would have to find designers to make them. And now, 3D print customization can be used to make ergonomic dishes, and even help people with disabilities.

Tuesday, June 13, 2017

Watch the American Drama "Pure Genius" Know How to Reveal the Significance of Medical 3D Printing?

For everyone without a medical background, medical treatment is often revolutionary. But Xiao Bian found a hospital theatre where pure genius's highly medical solutions often relied on the recently established medical procedures. In other words, controversial treatment procedures usually come from actual medical breakthroughs already in use by hospitals. This can be fun from some drama series (doctors usually don't feel, but we do). This series of pilot drama on the high-tech medical supplies, reflects the application of 3D printing in the hospital growing on heart model 3D print to solve especially tense situation.

Of course, the average reader will know that the 3D print model can increasingly be found in hospitals around the world, especially for very unusual and highly complex surgeries. In the most extreme cases, what we've seen is this 3D print heart model, which helped save a five day old baby from congenital heart defects. Just two years ago, these types of projects were disposable and rare, but many hospitals are now increasingly systematized in the production of these 3D print surgical models. Through collaboration with the Arizona State University, Phoenix children's hospital through their heart 3D printing laboratory, in fact, regulate the production of these 3D print heart model. The same episode now appears on TV, "pure genius".

The emergence of the 3D print surgical model in the mainstream show really illustrates how far this 3D printing technology is. The series itself was launched last Thursday, and is actually focused on extensive medical solutions driven by these gadgets. The problem is genius James Bell (Augustus Prew), a young billionaire entrepreneur, a rare complication, such as congenital heart defects with free treatment of high-tech revolution.

This is especially true in medical drama, but this 3D print solution has been used regularly at Phoenix children's hospital. In fact, according to statistics from universities and hospitals, there are about two 3D print heart models per week. In general, they provide surgeons with the data needed to plan an operation before entering any patient.

The heart of 3D printing laboratory has actually been developed for a long time, its origin can be traced back to 2010, when the ASU engineering professor David Freixas began recruiting professional art as his image processing laboratory - they can see the possibility of new technology. Justin Ryan is one of them and has been accepted into graduate programs in biomedical engineering. He is now running the Cardiac 3D printing laboratory.

3D printing has now been considered a medical potential, but it doesn't have any use, because 3D print accurate heart models may take weeks, and by then patients may have died. Through the efforts of Ryan and his team, they actually implemented the model in 2012, and with the help of the leadership of the Phoenix children's Hospital, they bought a 3D printer. "A printer in the hospital means we're next door," Ryan said. "The surgeon can look at the image and make several adjustments, and then we can print it once.".

Now, the heart model of patients at Feinikesi children's hospital can print 3D in 9 hours or less, and has produced more than 300. This allows the heart 3D printing laboratory to be the most manufactured surgical model 3D printer in the United States, and they are also manufactured for other local hospitals. Even adult patients benefit from this 3D printing process. In addition to the heart, they are also 3D printing, cancer and so on.

"Not only print, tell the surgeon before the surgery, it helps the child to figure out what the tumor actually looks like," Ryan said. "After the operation, we gave the patient a 3D print of the tumor and let him or her smash it.". Although pure genuis is lagging behind in some respects, the next step in medical 3D printing is not enough. Ryan and his team are also looking for skin cell tests and hope to experiment with liver cells, but they estimate that it may take decades for 3D printing organs to be realistic. But some of them, such as 3D printed heart valves, can be implemented in a year or five. They say 3D print skeletons and other implants, 3D print bones from cancer patients, have also been put on the agenda.

Sunday, June 11, 2017

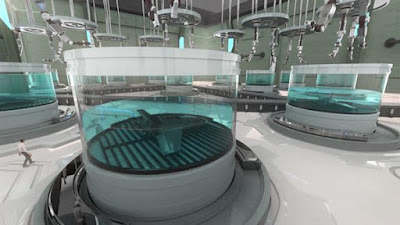

3D Printing Satellite Technology, This is not a Dream or Science Fiction

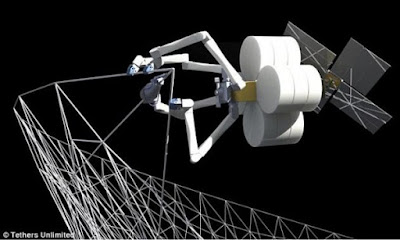

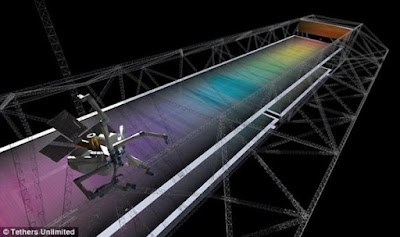

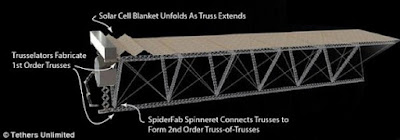

According to foreign media reports, a group of machine spiders in space orbit spacecraft or 3D printing satellite, this is not a dream or science fiction, but may soon become a reality. The US cable unlimited company, supported by NASA, recently reached a cooperation agreement with the US commercial satellite company Lara space systems, and the two sides will work together on the development of machine spiders. This strange machine spider will be able to use 3D printing technology to directly manufacture parts of space systems in space.

Once the SpiderFab project is successful, there will be a large number of machine spiders busy in space. They can print various giant space system structures and assemble them effectively through 3D printing equipment.

This approach will help us to create extremely large space systems, such as solar arrays and soccer field sized antennas larger than ten times or even hundreds of times larger than today.

The R & D program is called the "SpiderFab" program. According to experts, the first plan to launch a machine to orbit, to test whether it can print parts and assembly of the whole structure, these components include solar panels, antennas, sensors and spacecraft or satellite and other parts etc.. The ultimate goal of the project, however, is more sci-fi. If the research and development is successful, there will be a large number of machine spiders busy in space. They can print huge structures and assemble them effectively through 3D printing equipment. By then, satellites, spacecraft and other equipment will be made directly in space, which will help humans build larger spacecraft or satellites to orbit the earth.

The brains of this "smart spider" are made by the cable unlimited company in Washington, U. S. a.. Cable no limit company and the United States commercial satellite company Lara space systems signed a cooperation agreement, the two sides will be committed to the development of space 3D printing machine spider research and development. Firmamentum, a subsidiary of cable no limit, will test its "Trusselator" technology in the dragonfly program of Lara space systems. The dragonfly project will test the construction of communications satellites on orbit, while the Trusselator technology mainly produces lightweight frame trusses to support solar panels, antennas and sensors.

The Trusselator technology will create high-performance support structures through 3D printing technology and automated assembly technology.

"The dragonfly project provides us with an excellent opportunity to demonstrate space manufacturing technology," said Dr. rob Hoyt, CEO of Firmamentum." Lara space systems CTO Mateo - Dr. Jana said, "the development of next generation communication satellite and space systems will rely mainly on manufacturing technology progress." It is not clear when the trials will be conducted.

The existing satellite to enter the orbit of the earth, when they are in the process through the earth's atmosphere, you must be folded and hidden in the protective cover, to prevent overheating and burned or destroyed by resistance. While making satellite components in space, you only need to compress the machine spiders and raw materials into the rocket and send them into space. As early as 2013, Hoyt had introduced such space manufacturing technology. "The raw materials needed to make these important components in orbit, such as fibers and polymers, can be compressed into a very tight form and packaged into a smaller, cheaper launch medium.". On track, the machine spider manufacturing system will process the raw materials and make a huge structure. This approach will help us to produce antennas or solar arrays that are ten times or even hundreds of times larger than now. These devices will be able to provide greater energy, greater bandwidth, higher resolution, and higher sensitivity for a wider range of space missions."

Once the SpiderFab project is successful, there will be a large number of machine spiders busy in space. They can print various giant space system structures and assemble them effectively through 3D printing equipment.

The R & D program is called the "SpiderFab" program. According to experts, the first plan to launch a machine to orbit, to test whether it can print parts and assembly of the whole structure, these components include solar panels, antennas, sensors and spacecraft or satellite and other parts etc.. The ultimate goal of the project, however, is more sci-fi. If the research and development is successful, there will be a large number of machine spiders busy in space. They can print huge structures and assemble them effectively through 3D printing equipment. By then, satellites, spacecraft and other equipment will be made directly in space, which will help humans build larger spacecraft or satellites to orbit the earth.

The brains of this "smart spider" are made by the cable unlimited company in Washington, U. S. a.. Cable no limit company and the United States commercial satellite company Lara space systems signed a cooperation agreement, the two sides will be committed to the development of space 3D printing machine spider research and development. Firmamentum, a subsidiary of cable no limit, will test its "Trusselator" technology in the dragonfly program of Lara space systems. The dragonfly project will test the construction of communications satellites on orbit, while the Trusselator technology mainly produces lightweight frame trusses to support solar panels, antennas and sensors.

The Trusselator technology will create high-performance support structures through 3D printing technology and automated assembly technology.

"The dragonfly project provides us with an excellent opportunity to demonstrate space manufacturing technology," said Dr. rob Hoyt, CEO of Firmamentum." Lara space systems CTO Mateo - Dr. Jana said, "the development of next generation communication satellite and space systems will rely mainly on manufacturing technology progress." It is not clear when the trials will be conducted.

The existing satellite to enter the orbit of the earth, when they are in the process through the earth's atmosphere, you must be folded and hidden in the protective cover, to prevent overheating and burned or destroyed by resistance. While making satellite components in space, you only need to compress the machine spiders and raw materials into the rocket and send them into space. As early as 2013, Hoyt had introduced such space manufacturing technology. "The raw materials needed to make these important components in orbit, such as fibers and polymers, can be compressed into a very tight form and packaged into a smaller, cheaper launch medium.". On track, the machine spider manufacturing system will process the raw materials and make a huge structure. This approach will help us to produce antennas or solar arrays that are ten times or even hundreds of times larger than now. These devices will be able to provide greater energy, greater bandwidth, higher resolution, and higher sensitivity for a wider range of space missions."

Friday, June 9, 2017

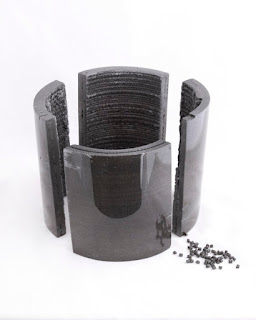

Another Major Breakthrough in 3D Printing - The Impact of Magnet 3D Printing in Manufacturing

For many of us, the first time we heard about magnets was the science course at elementary school. But as a matter of fact, many of the world we live in is dependent on the forces of mutual restraint and attraction, such as generators, electric horns, trains, cranes......

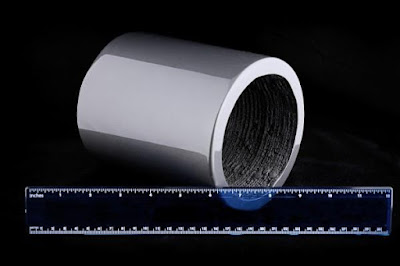

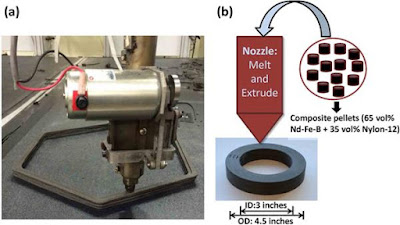

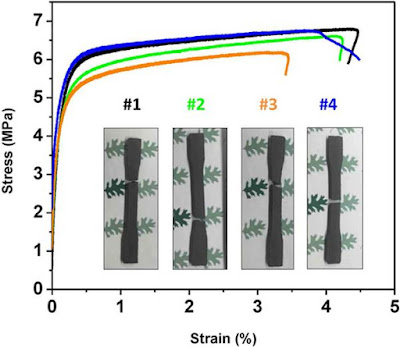

Recently, the Oak Ridge National Laboratory (ORNL) announced that their permanent magnets would be better than conventional magnets. The permanent magnet itself forms a permanent magnetic field, so it can continue to operate without recharging. The development of this permanent magnet may prove a great success for the development of 3D printing technology. According to ORNL's research, mixing magnetic powders with polymers as binders, and then forming preferred shapes by material deposition, and then using several processing methods to form magnet mixing materials, such as extrusion. At present, the idea of magnet 3D printing is relatively new, and according to the evidence, this technology has been recognized by more and more colleges and universities around the world.

"Manufacturing is changing rapidly. A customer may need as many as 50 different designs, so this universal magnet will be a good solution."." Liang Li ORNL researchers said, "the traditional process of injection mold requires a fee in the design to create a mold, but 3D printing technology, it can quickly complete the design through the computer aided design function". The composite particles are formed by mixing 65% of the isotropic NdFeB magnetic powder with 35% of the polyamide (nylon). The production company then molded the composite particles into a variety of shapes by dissolving and pressing them. Nylon is a very common and widely used laser sintering 3D printing material. After such a mixing method, it becomes a permanent magnet mixture suitable for 3D printing. It is proved that the extruded nylon magnet composite particles can exhibit higher accuracy than other materials such as plastic filament.

3D printer using BAAM system itself has a huge amount of construction, with 3.56*1.65*0.86 meters of molding space, and has a single screw extruder, print bed and hot bed. Therefore, the utility model can directly stack the printing pieces on an aluminum board at the printing temperature of 270 DEG C, and can provide maximum adhesive force. In addition, this innovative method of manufacturing permanent magnets can effectively reduce the waste of 30% to 50% of the waste generated during the 3D printing process. The reason is simple, because in the process, any material can be obtained and recycled. Considering that NdFeB magnetic powder is the most permanent magnetic material so far, it will be a big surprise for 3D printing material. Due to the addition of permanent magnetic material, printing complex shapes of motors and engines will become a less difficult task. Because it eliminates many of the limitations of today's manufacturing methods." Alex King, head of materials research institute.

For the moment, the research is still new, so further research and exploration is still needed in the laboratory. But the team's work has laid the foundation for its future success and provides enormous potential for the use of magnetic Science in consumer goods. I believe we will also be the same as Xiao Bian thought, if 3D printing technology can really bring us more powerful and more flexible products, then its development will be overwhelming. The permanent magnetic material developed by ORNL is undoubtedly an important material to change the world.

|

| Magnet 3D Printing in Manufacturing |

"Manufacturing is changing rapidly. A customer may need as many as 50 different designs, so this universal magnet will be a good solution."." Liang Li ORNL researchers said, "the traditional process of injection mold requires a fee in the design to create a mold, but 3D printing technology, it can quickly complete the design through the computer aided design function". The composite particles are formed by mixing 65% of the isotropic NdFeB magnetic powder with 35% of the polyamide (nylon). The production company then molded the composite particles into a variety of shapes by dissolving and pressing them. Nylon is a very common and widely used laser sintering 3D printing material. After such a mixing method, it becomes a permanent magnet mixture suitable for 3D printing. It is proved that the extruded nylon magnet composite particles can exhibit higher accuracy than other materials such as plastic filament.

3D printer using BAAM system itself has a huge amount of construction, with 3.56*1.65*0.86 meters of molding space, and has a single screw extruder, print bed and hot bed. Therefore, the utility model can directly stack the printing pieces on an aluminum board at the printing temperature of 270 DEG C, and can provide maximum adhesive force. In addition, this innovative method of manufacturing permanent magnets can effectively reduce the waste of 30% to 50% of the waste generated during the 3D printing process. The reason is simple, because in the process, any material can be obtained and recycled. Considering that NdFeB magnetic powder is the most permanent magnetic material so far, it will be a big surprise for 3D printing material. Due to the addition of permanent magnetic material, printing complex shapes of motors and engines will become a less difficult task. Because it eliminates many of the limitations of today's manufacturing methods." Alex King, head of materials research institute.

For the moment, the research is still new, so further research and exploration is still needed in the laboratory. But the team's work has laid the foundation for its future success and provides enormous potential for the use of magnetic Science in consumer goods. I believe we will also be the same as Xiao Bian thought, if 3D printing technology can really bring us more powerful and more flexible products, then its development will be overwhelming. The permanent magnetic material developed by ORNL is undoubtedly an important material to change the world.

Wednesday, June 7, 2017

Development trend and practical application of high performance 3D printing photosensitive resin

The day before, the well-known light curing desktop 3D printer manufacturer Formlabs company released the launch of a series of newly developed 3D printing photosensitive resin, these materials can make your Form 2 Desktop 3D printer to get more power in terms of rapid prototyping and mold.

These new resins can simulate a whole range of injection molded plastics without the weakness of these materials. So if you are looking for a ABS like easy to use plastic prototype, or can durable resin concept you polypropylene products, or in just a few minutes to create the function mold of heat resistant resin, even for new tires and the prototype rubber flexible resin, Formlabs company it can provide corresponding products for you.

Of course, these products are for those who have the 3D print for professional users of rapid prototyping, such as design and engineering consultants, but ordinary lovers or guests can also design their own want to achieve with it.

Of course, these products are for those who have the 3D print for professional users of rapid prototyping, such as design and engineering consultants, but ordinary lovers or guests can also design their own want to achieve with it.

It is reported that, Formlabs company was founded in 2011, specializing in the production of commercial SLA 3D printer, its products can be used in product design, dentistry, medical model manufacturing, including many fields. The resin products are aimed at the Formlabs company SLA 3D printer development, which means that designers can before you can print products simply can not use it, and according to the different materials show their own appearance. According to the company, prototypes printed with these resins can be used for basic testing and verification.

So if you want to make a product of ABS material, you can use its reformulated Tough Resin and complete your conceptualization and prototyping on your desktop with your Form 2 SLA 3D printer. This engineering resin creates a balance between strength and elongation so that it is sufficiently strong under pressure and has better impact resistance than other plastic products.

In addition, they are also resistant to deformation, so if you need absolute precision or make prototypes that require a precise combination of components, this Tough Resin is the ideal choice. And its strength is high enough to make fastener joints.

Another Durable Resin resin products, it can be used to simulate the polypropylene, the latter is a relatively common material, relatively wide range of applications, can be made from all the products with a flexible locking hinge to the bumper of the car, and has very good gloss.

As for its high temperature resistant High, Temp, Resin, at 0.45 MPa, the deformation temperature can reach 289 degrees celsius. So if you need to make a thermoset mold, that might be the answer you've been looking for.

These new resins can simulate a whole range of injection molded plastics without the weakness of these materials. So if you are looking for a ABS like easy to use plastic prototype, or can durable resin concept you polypropylene products, or in just a few minutes to create the function mold of heat resistant resin, even for new tires and the prototype rubber flexible resin, Formlabs company it can provide corresponding products for you.

Of course, these products are for those who have the 3D print for professional users of rapid prototyping, such as design and engineering consultants, but ordinary lovers or guests can also design their own want to achieve with it.

Of course, these products are for those who have the 3D print for professional users of rapid prototyping, such as design and engineering consultants, but ordinary lovers or guests can also design their own want to achieve with it.It is reported that, Formlabs company was founded in 2011, specializing in the production of commercial SLA 3D printer, its products can be used in product design, dentistry, medical model manufacturing, including many fields. The resin products are aimed at the Formlabs company SLA 3D printer development, which means that designers can before you can print products simply can not use it, and according to the different materials show their own appearance. According to the company, prototypes printed with these resins can be used for basic testing and verification.

So if you want to make a product of ABS material, you can use its reformulated Tough Resin and complete your conceptualization and prototyping on your desktop with your Form 2 SLA 3D printer. This engineering resin creates a balance between strength and elongation so that it is sufficiently strong under pressure and has better impact resistance than other plastic products.

In addition, they are also resistant to deformation, so if you need absolute precision or make prototypes that require a precise combination of components, this Tough Resin is the ideal choice. And its strength is high enough to make fastener joints.

Another Durable Resin resin products, it can be used to simulate the polypropylene, the latter is a relatively common material, relatively wide range of applications, can be made from all the products with a flexible locking hinge to the bumper of the car, and has very good gloss.

As for its high temperature resistant High, Temp, Resin, at 0.45 MPa, the deformation temperature can reach 289 degrees celsius. So if you need to make a thermoset mold, that might be the answer you've been looking for.

Monday, June 5, 2017

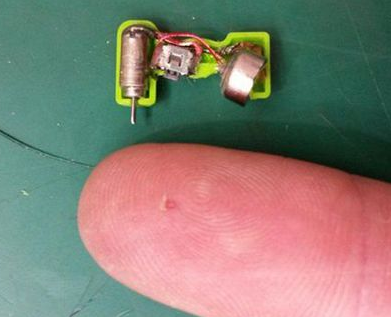

The Smallest 3D Printed Electric Drill in The World Can Enter Your Blood Vessels

It is understood that the entire print object without any support mechanism, he will be micro drill is divided into three parts, all printed out, spent a total of 25 minutes. Although 3D printing is really easy to do, but the assembly does not seem so easy. The three sections include a chuck with two outer housings and a fixed motor shaft. The Abernethy uses the battery on the hearing aid as a power source, and installs a small button and a micro motor. In order to solve the wiring problem, he peeled off the headphone cord and used it. In order to assemble the drill, Abernethy spent more than 3 hours of time, because in the connection process, the wire is always broken, he must try to do them fixed in one place, but also to avoid the short circuit of the battery, it sounds too painful, this is a nightmare!

When all the work is completed, a mini electric drill was now in front of you, it is only 17 mm high and 7.5 mm wide, 13 mm long, and has a 0.5 mm drill, can be drilled through the soft objects. It is said to be the smallest electric drill in the world, completely written into the Guinness book of world records.

Friday, June 2, 2017

The UK is developing Chemputer capable of producing 3D drones for military drones

According to BBC reports, the British University of Glasgow (University of Glasgow) the scientists are to cooperate with the country's leading defense company BAE Systems R & D team, jointly developed a chemical reaction based on 3D printer Chemputer, this 3D printer can scratch the "growth" of highly advanced customization of UAV in a few weeks.

This is a concept from the future of the world is officially announced in the year before the opening of the Farnborough international air show. Chemputer sounds like a science fiction directly, but it's actually a 3D printer that can be built at a molecular level that can grow all the components from the wing to the electronic system. However, Chemputer is still in the process of research and development.

BAE Systems was founded in November 1999 by the British Aerospace Corporation (BAe) and Marconi electronic systems (Marconi Electronic Systems), and is currently the world's second largest defense contractor. The focus of the company's operations include security defense, aerospace, it is headquartered in London and Farnborough, business all over the world.

According to the company, the Chemputer 3D printer, in theory, is a combination of synthetic chemistry and materials chemistry that can be used in laboratory chemicals to grow out of small uavs. This breakthrough has once achieved, making an airplane, may only need a few weeks on the line, the production speed, can be the nearest production in the theater, and can accelerate the rate of chemical reaction at the molecular level, do not need to wait long and complex supply chain, no doubt for the military brought great advantage.

To turn this revolutionary concept into reality, the company found a collaboration with Lee Cronin, a professor at the University of Glasgow, who offered industrial advice. In short, their proposed 3D printer prints environmentally sustainable molecules rather than objects or layered structures. With the aid of additives and nutrients, these molecules develop into any desired (functional) shape. The goal is clearly ambitious, but not impossible. Many researchers are studying how to use chemical synthesis technology, even if it is suitable for the manufacture of complex electronic systems, still need considerable effort. It could also be used to build parts for large manned aircraft.

Prof Cronin acknowledges that growing "tiny, basic drones" in a chemical way is a big challenge. "It was a very exciting time in the history of chemistry.". We have worked out a development route to digital synthesis and material chemistry, hope to be able to achieve in a machine from scratch to achieve assembly of complex objects at some stage in the future, and the lowest in the process will help mankind. The creation of small aircraft would be very challenging, but I am convinced that creative thinking and the tendency toward unlimited powerful digital technology will eventually lead to the realization of complex digital programming in chemical and material systems." He said.

This is a concept from the future of the world is officially announced in the year before the opening of the Farnborough international air show. Chemputer sounds like a science fiction directly, but it's actually a 3D printer that can be built at a molecular level that can grow all the components from the wing to the electronic system. However, Chemputer is still in the process of research and development.

BAE Systems was founded in November 1999 by the British Aerospace Corporation (BAe) and Marconi electronic systems (Marconi Electronic Systems), and is currently the world's second largest defense contractor. The focus of the company's operations include security defense, aerospace, it is headquartered in London and Farnborough, business all over the world.

According to the company, the Chemputer 3D printer, in theory, is a combination of synthetic chemistry and materials chemistry that can be used in laboratory chemicals to grow out of small uavs. This breakthrough has once achieved, making an airplane, may only need a few weeks on the line, the production speed, can be the nearest production in the theater, and can accelerate the rate of chemical reaction at the molecular level, do not need to wait long and complex supply chain, no doubt for the military brought great advantage.

To turn this revolutionary concept into reality, the company found a collaboration with Lee Cronin, a professor at the University of Glasgow, who offered industrial advice. In short, their proposed 3D printer prints environmentally sustainable molecules rather than objects or layered structures. With the aid of additives and nutrients, these molecules develop into any desired (functional) shape. The goal is clearly ambitious, but not impossible. Many researchers are studying how to use chemical synthesis technology, even if it is suitable for the manufacture of complex electronic systems, still need considerable effort. It could also be used to build parts for large manned aircraft.

Prof Cronin acknowledges that growing "tiny, basic drones" in a chemical way is a big challenge. "It was a very exciting time in the history of chemistry.". We have worked out a development route to digital synthesis and material chemistry, hope to be able to achieve in a machine from scratch to achieve assembly of complex objects at some stage in the future, and the lowest in the process will help mankind. The creation of small aircraft would be very challenging, but I am convinced that creative thinking and the tendency toward unlimited powerful digital technology will eventually lead to the realization of complex digital programming in chemical and material systems." He said.

Subscribe to:

Posts (Atom)